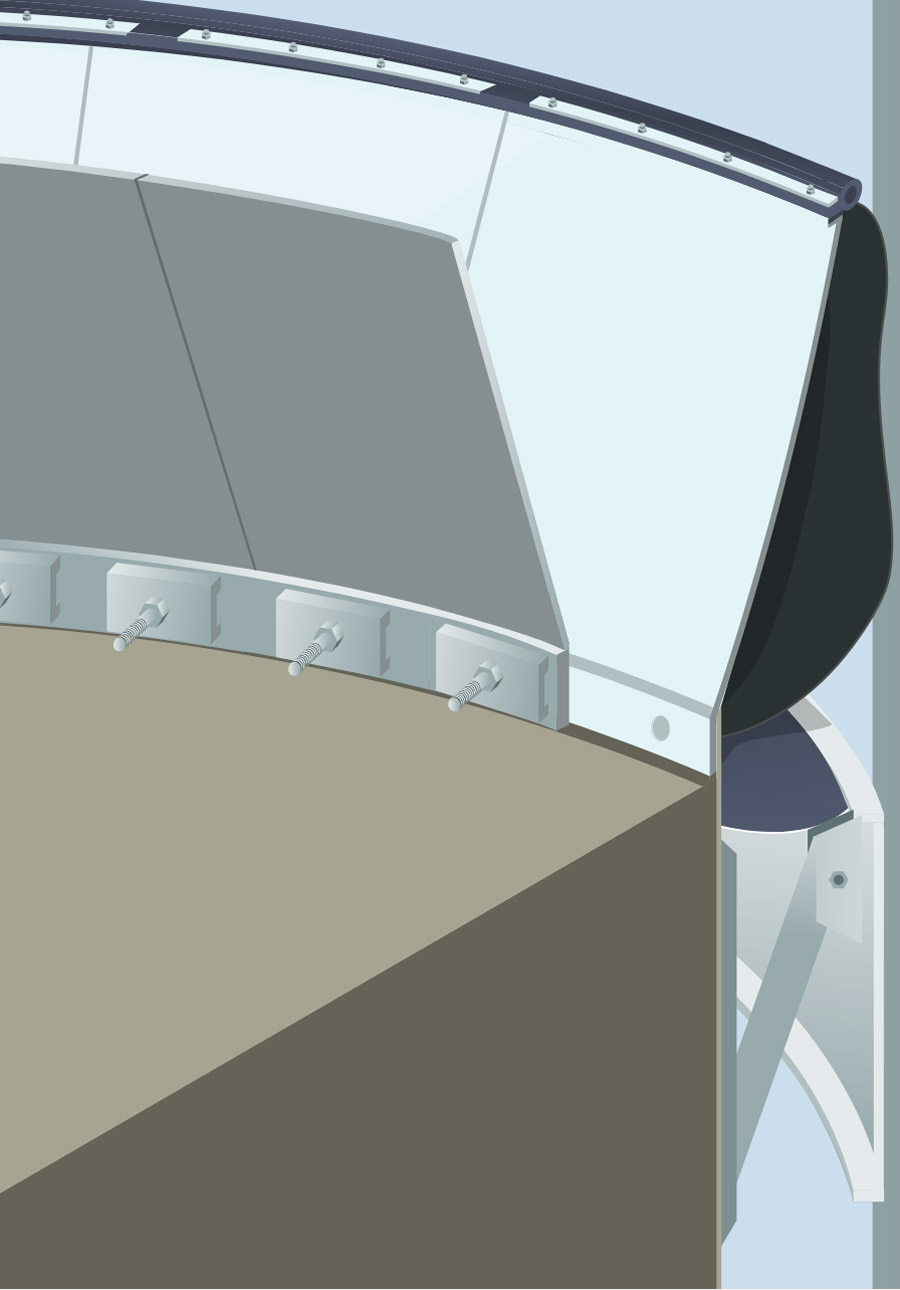

Sandborn Mechanical Sealing System

Leading with innovation, sealing with precision.

Expertise Delivers

40+ years of

proven custom

design expertise

3,000+

installations worldwide

Designed to meet

all regulatory standards

Can be installed while

tank remains ‘In-Service’

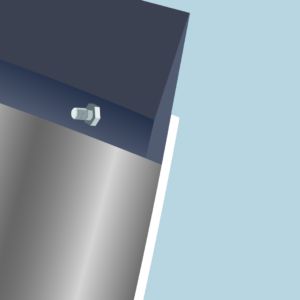

No welding or

flame cutting required

for installation

SCAQMD, BAAQMD

and EPA approved

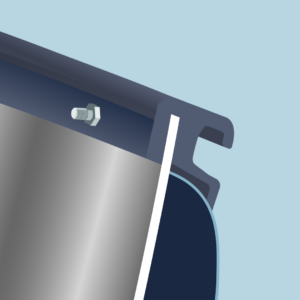

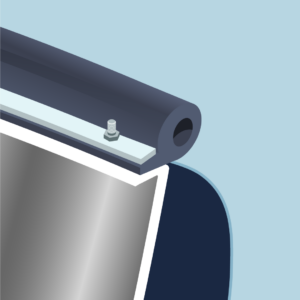

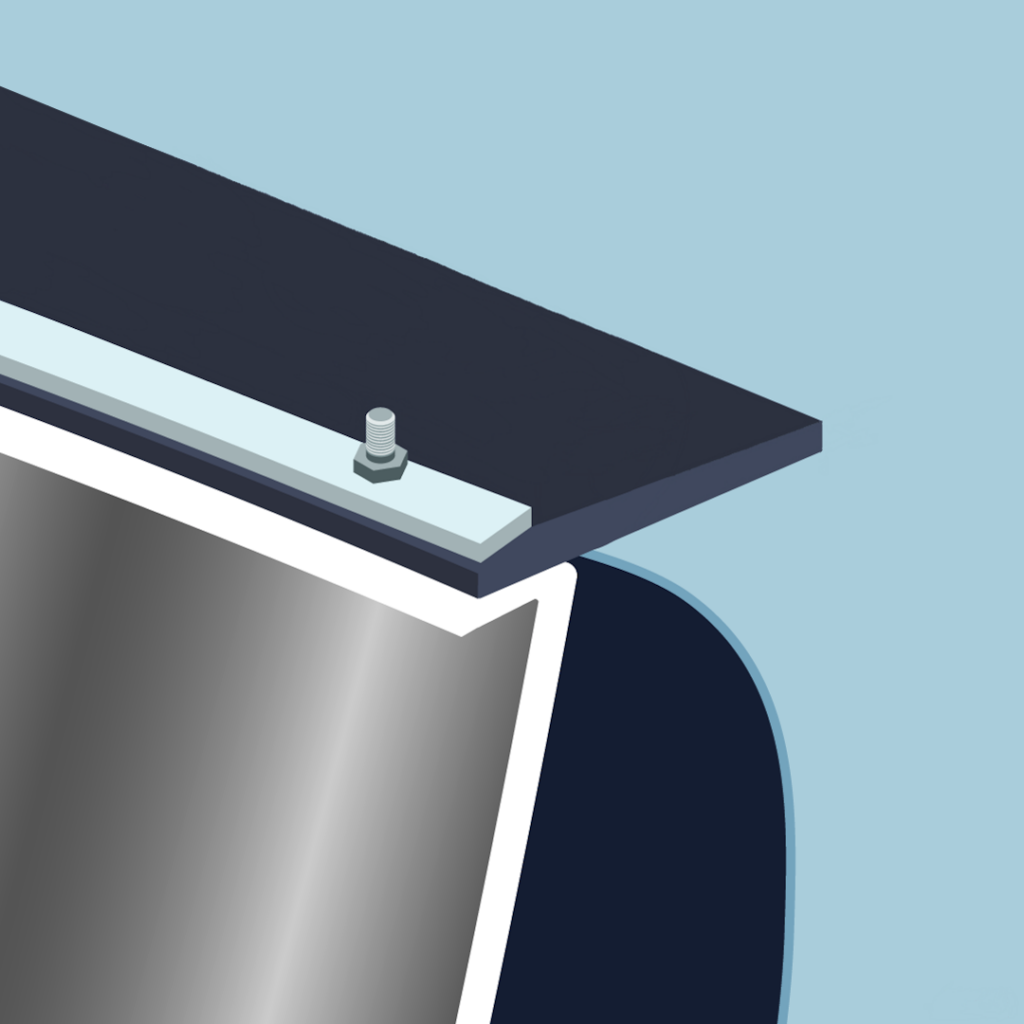

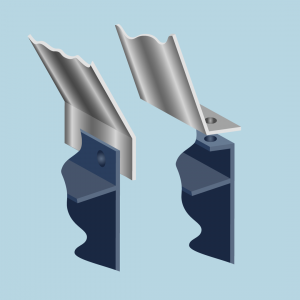

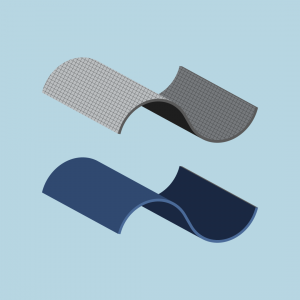

Sandborn Seal Assemblies provide the best emission control in the industry

Each Sandborn Seal Assembly is fully tested prior to shipment to site to ensure a properly functioning seal throughout the entire operating parameters of the tank. Each seal component is verified to ensure smooth operations, with closing forces recorded and provided for each seal assembly.

Our unique testing equipment has been engineered to simulate the conditions of actual floating roof operation, ensuring a Sandborn Seal Assembly will provide the best emission control possible.

-

Fully tested prior to shipment to site

-

Verified to ensure smooth operations

-

Engineered to simulate the conditions of actual floating roof operation

-

Guaranteed to provide the highest emission control possible