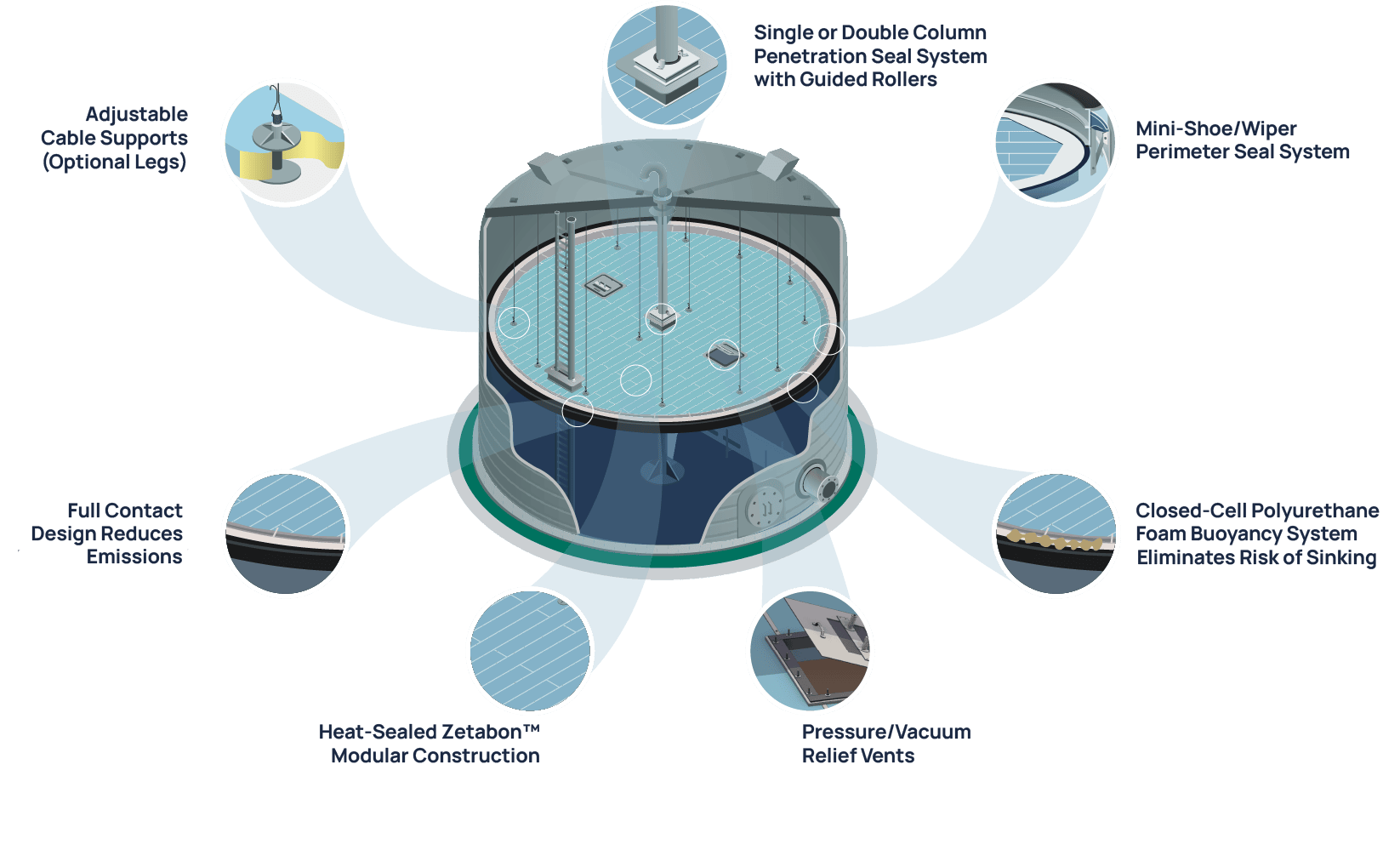

Sandborn Full Contact Floating Roofs

Key features that ensure optimal operational efficiency.

Sandborn Transportable Internal Floating Roof Systems

Our Transportable Internal Floating Roofs (IFRs) serve diverse industries and scenarios. These versatile IFRs are designed for easy mobility and rapid deployment, enabling our client partners to put them into immediate service upon arrival at the site.

Many of our valued client partners opt for these transportable solutions as a cost-effective alternative to constructing permanent storage tanks, particularly when their storage requirements are temporary in nature.

Removable grid

support system

Full contact uniform

peripheral seal

Eliminates emissions

Insulation R-value 20

Specifically designed for production tank service

Exclusive 10-Year

anti-Sinking Warranty

Aluminum Pontoon Floating Roof Systems

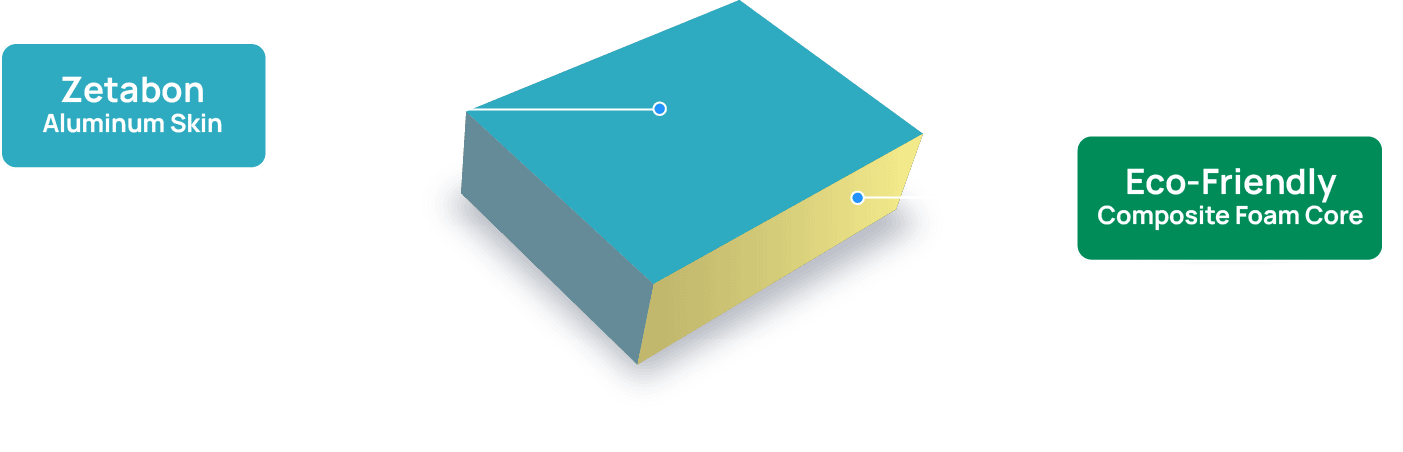

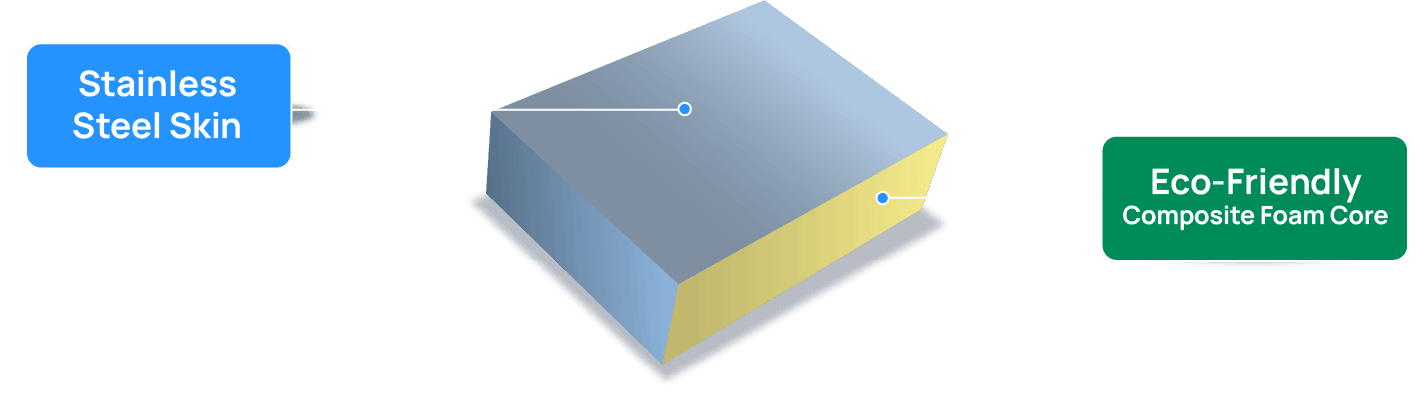

Aluminum pontoon style floating roof systems are used primarily in light-duty/refined product storage applications. Giving our client partners the benefit of choice, they are available in all Aluminum, all Stainless Steel or mixed Aluminum Skin with Stainless Steel Wetted Parts (hybrid), and are compatible with most refined products, including Ethanol. Aluminum pontoon style floating roofs are available upon request.

-

Adjustable Aluminum Leg or Stainless-Steel Adjustable Cable Supports

-

Multiple Perimeter Sealing Systems available

-

Aluminum or Stainless-Steel Pontoons

-

Can be installed through a standard API Manway